Example with a study case using Comsol AC/DC

(source : https://www.comsol.com/paper/modeling-pcb-based-inductive-position-sensors-with-the-comsol-acdc-module-122391)

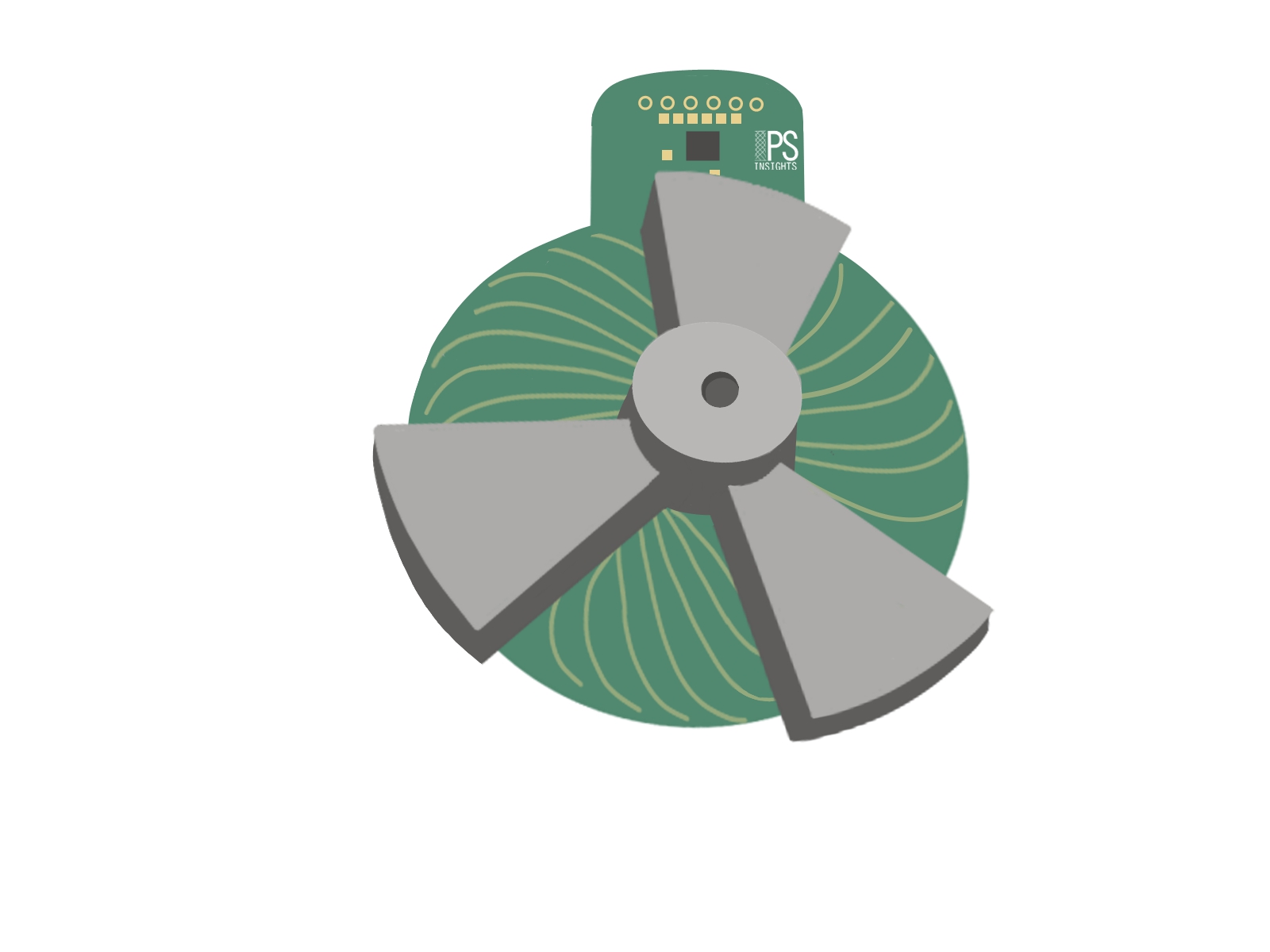

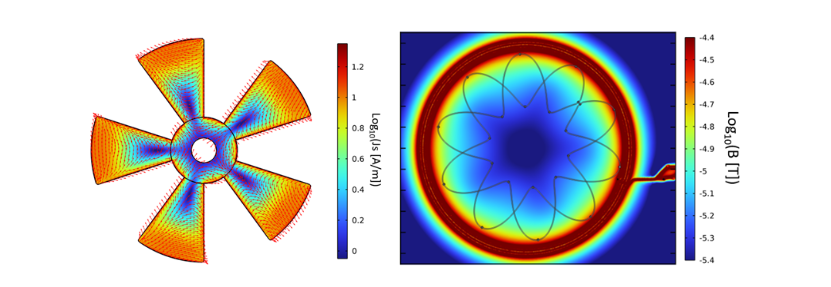

Figure 1. Target surface current distribution and Coil plane magnetic field distribution.

Context

In a perfect world without mechanical or physical interferences, inductive position sensors (IPS) would operate with minimal error. However, real-world applications always involve non-ideal conditions. Various factors such as additional metallic parts, feeding wires, multilayer PCB designs, and nearby ground planes can introduce accuracy errors. Evaluating and optimizing these factors is essential for accurate IPS performance.

This study focuses on three key factors affecting IPS accuracy using COMSOL simulations:

- Number of PCB Layers (2 vs. 4)

- Feeding Wires Connecting Rx Coils to the IC

- Nearby Metallic Ground Planes

Methodology of the study

Starting from an ideal configuration, non-idealities are progressively introduced. The following protocol determines the accuracy for each configuration:

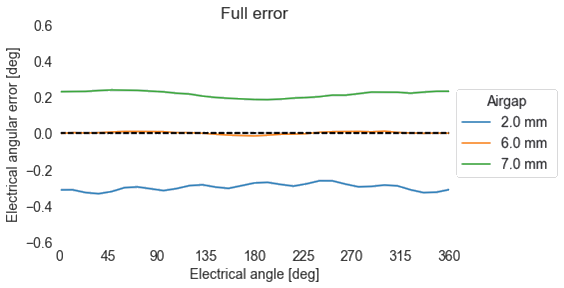

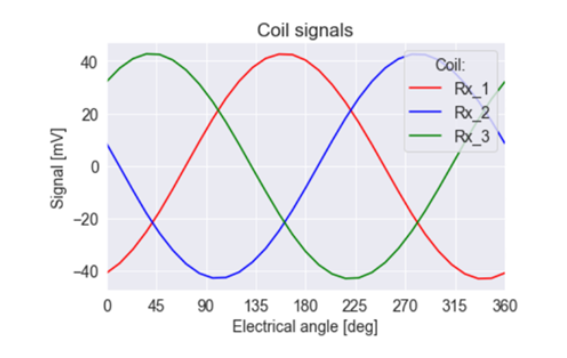

- Simulations: Perform simulations with different air gaps between coils and the target, recording the Rx signal amplitude.

- Angle Calculation: Calculate the sensor’s angle using Clarke’s transformation on the Rx signals followed by an arctangent calculation.

- Accuracy Assessment: Compare the calculated angle with the target’s reference position.

This process highlights the impact of PCB design modifications on system accuracy.

Figure2. Simulated Rx coils signals amplitude vs. target position over one full electrical period

Results

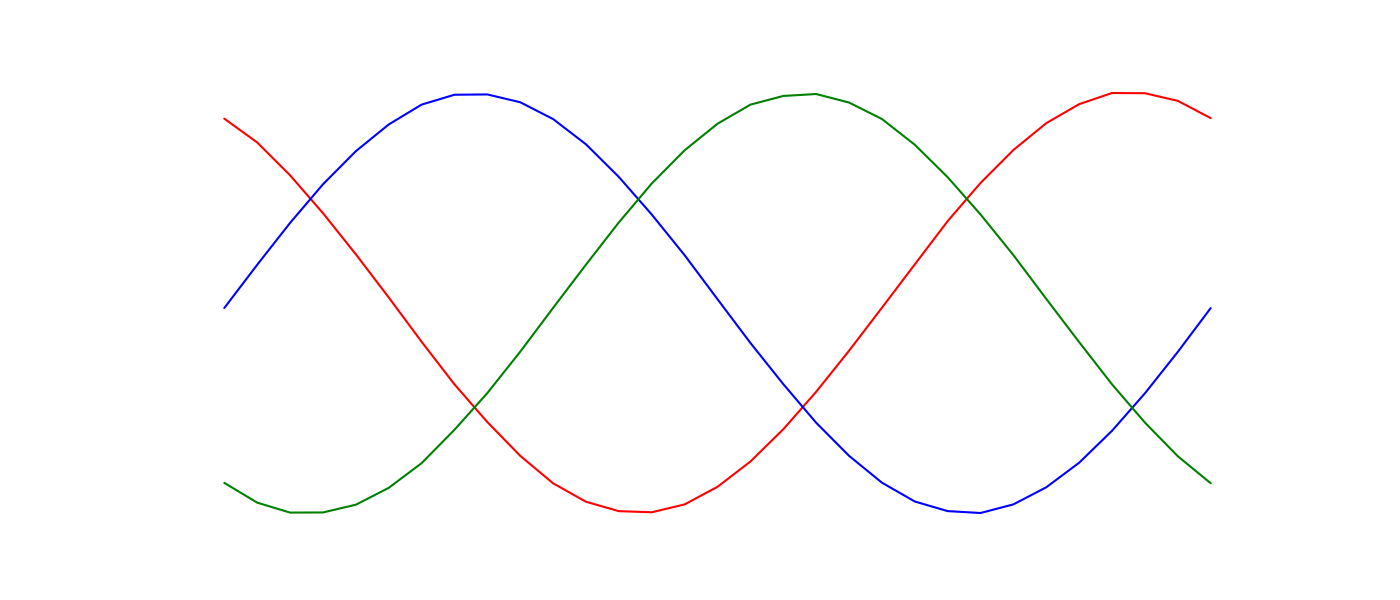

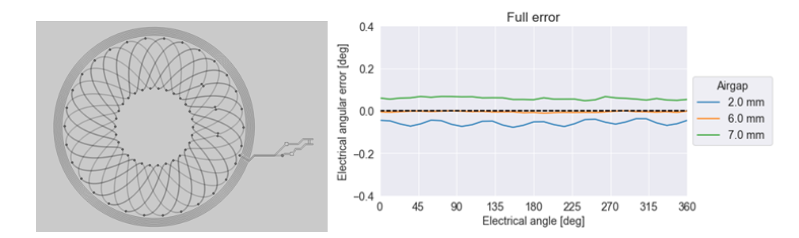

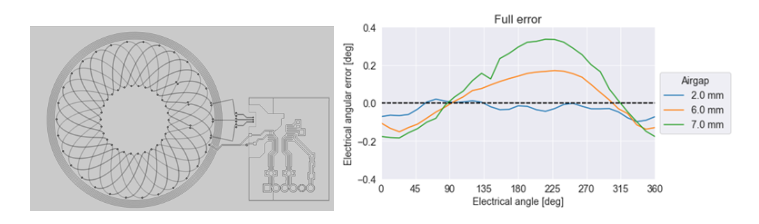

- Ideal Case: 4-Layer PCB

An ideal 4-layer PCB with 0.3 mm spacing between planes shows nearly perfect accuracy across various air gaps, as seen in Figure 3.

Figure 3. PCB design of an IPS in an ideal case– 4 layers and the accuracy associated

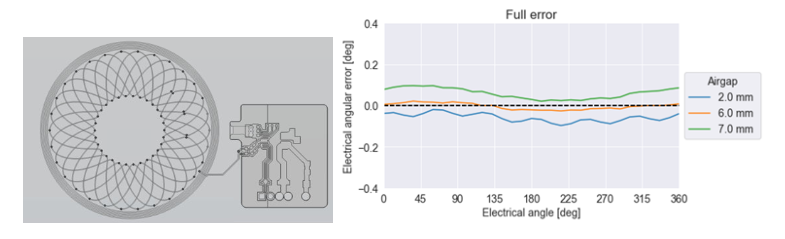

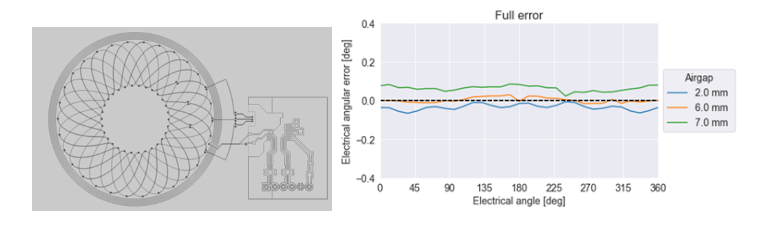

- Introducing a Ground Plane

Adding a metallic ground plane introduces a first harmonic error, increasing with the ground plane’s proximity to the coils (Figure 4).

Figure 4. PCB design including a ground plane – 4 layers and the accuracy associated

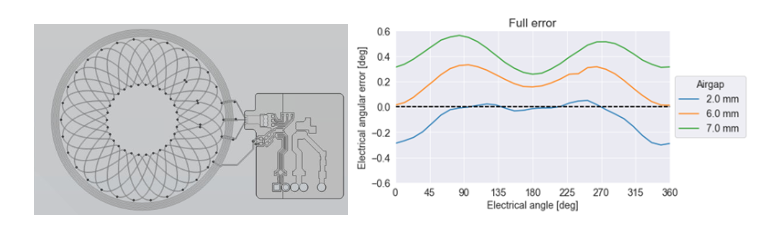

- Feeding Wires Configuration

Feeding wires introduce parasitic surfaces. Two configurations are tested:

- 60° Electrical Separation (Figure 5)

Figure 5. PCB design with 60° electrical feedings configuration – 4 layers and its accuracy

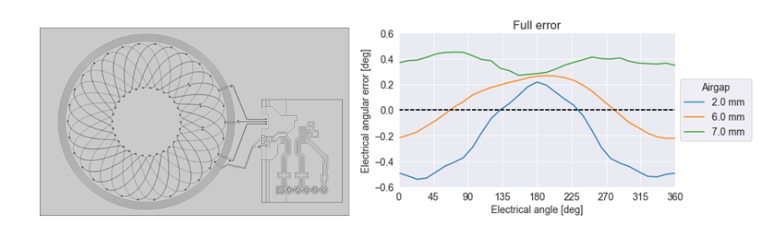

- 120° Electrical Separation (Figure 6)

Figure 6. PCB design with 120° electrical feedings configuration – 4 layers and its accuracy

The 120° electrical separation configuration demonstrates superior accuracy.

- 2-Layer PCB Configurations

For 2-layer PCBs with 1.6 mm spacing:

- 60° Electrical Separation (Figure 7)

Figure7. PCB design with 60° electrical feedings configuration – 2 layers and its accuracy

- 120° Electrical Separation (Figure 8)

Figure 8. PCB design with 120° electrical feedings configuration – 2 layers and its accuracy

Both configurations show significant errors due to larger horizontal parasitic surfaces from feeding lines, which are minimized in the 4-layer design.

Conclusion

Optimizing PCB design, especially the number of layers and the arrangement of feeding wires, is vital for minimizing accuracy errors in IPS. This study underscores the importance of careful PCB layout to ensure high-performance sensor operation in real-world applications.